Yes, even a slight warp will cause problems to your project. They are often undetectable until you start to do your finish work. Unfortunately, many new CNC router owners find this out the hard way.

HOW TO FLATTEN A WARPED, OR NON-PARALLEL SPOILBOARD

When your CNC router is first set up, it’s standard procedure to make sure the spoilboard is properly flattened before you start carving projects. That way, you can prevent these issues from the get-go.

And spoilboard surfacing (or flattening) is the standard procedure to do this.

We need to write a program, or use a utility program, to write a surfacing routine. Some CNC router control programs, like gSender, will do this for you.

It may sound intimidating to ‘write’ your own program to do this, but it is actually quite easy, provided you have design softyware to design your CNC router projects. There are videos on the IDC Woodcraft YouTube channel that cover this.

Some CNC router control programs, like gSender, will even write the surfacing routine for you.

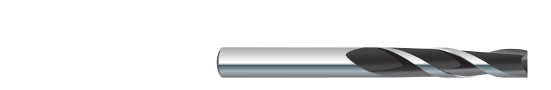

But, the one thing you must have to accomplish spoilboard flattening is a surfacing bit. It’s also called a spoilboard router bit, or flattening bit, or spoilboard cutter. The proper term is ‘surfacing bit‘.