Shop

Add this item

+

Add this item

+

Add this item

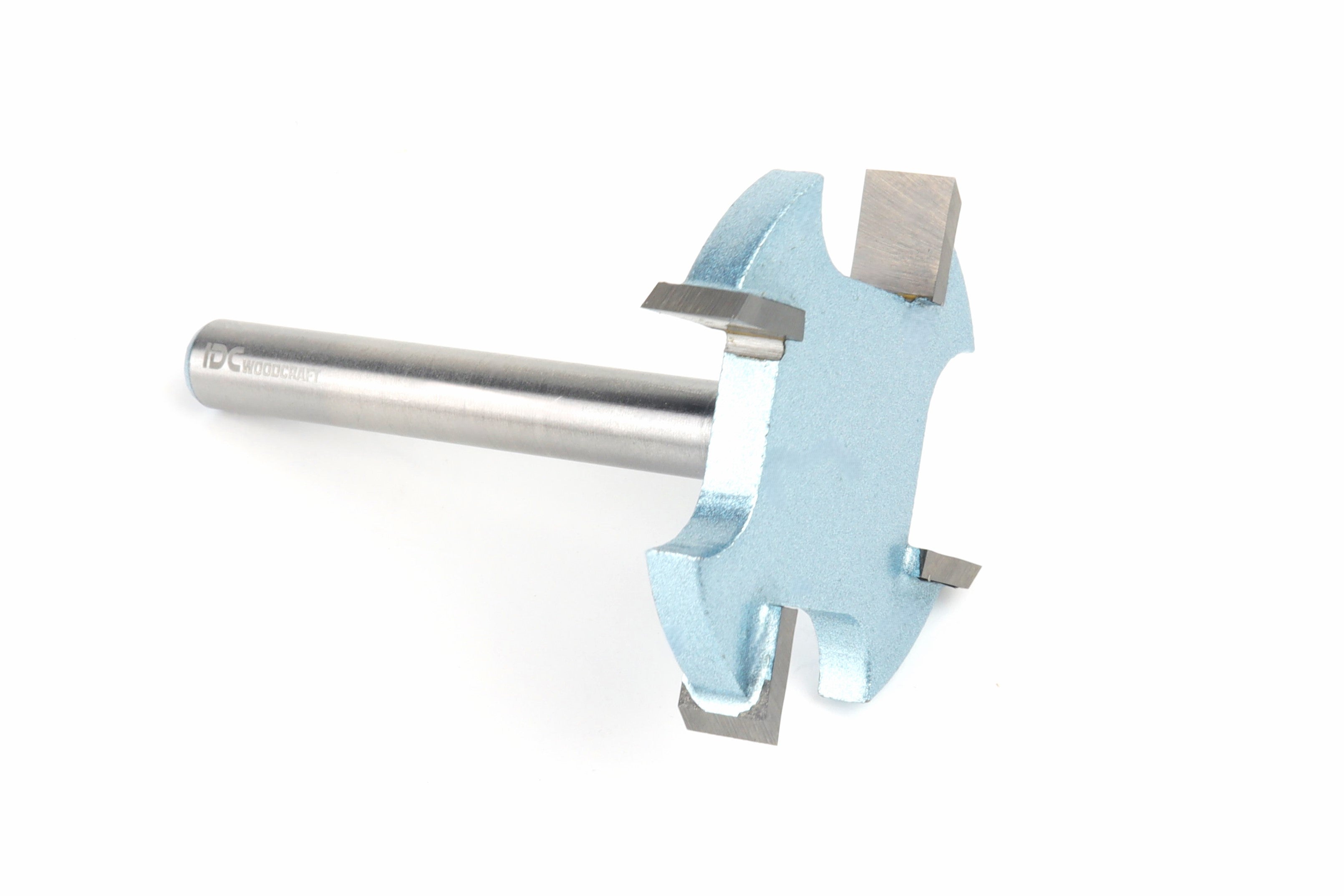

Level your CNC spoilboard and flatten slabs with this precision-engineered 1-1/2” Ultra-Smooth Cut Surfacing Bit for CNC routers with 1/4" shank.

This redesigned 4-flute CNC surfacing bit gives you cleaner cuts, faster feed rates, and longer tool life — helping you create perfect project surfaces with ease. Whether you're resurfacing your CNC spoilboard (also called a waste board or spoiler board), flattening slabs, or cleaning up warped project materials, this bit is an essential tool for any CNC owner.

Why is this bit better?

Unlike traditional 2- or 3-flute surfacing bits, this bit features a 4th flute to achieve an ultra-smooth finish on wood surfaces. Combined with a reduced forward cutting angle and a shallower grind angle on both the face and bottom, this surfacing bit exceeds the performance of all other bits in its class, giving you:

Why you need a surfacing bit:

Most spoilboards are not perfectly parallel to your CNC router’s motion. Without surfacing, your projects can come out uneven, and your bit may cut too deeply in high spots.

Using a surfacing bit ensures:

Spoilboard resurfacing is also a routine maintenance task, as your spoilboard surface will gradually wear from repeated use and need reconditioning.

Designed for hobby and semi-professional CNC users:

This 1.5” CNC surfacing bit is made specifically for hobbyists and small-shop CNC users who want professional-quality results. It allows effective cleanup and surfacing in one pass, even at higher feed rates, making spoilboard preparation and slab flattening faster and more efficient.

Fits all CNC routers with a 1/4” collet.

Applications:

A Note from Garrett (CEO of IDC Woodcraft)

I designed the Ultra-Smooth Cut Surfacing Bit Series because I was frustrated with the mediocre performance and short lifespan of surfacing bits typically sold on Amazon, and by many CNC bit suppliers. They simply didn’t deliver the results I wanted. So I redesigned it from the ground up to deliver the smooth finish and tool life you should expect from a surfacing bit. I’m proud to offer this bit to CNC creators who care about quality and getting the best results from their work.

To read more about what a spoilboard is, read this article or watch this video about surfacing bit feeds and speeds, or this video about how a surfacing flattening bit can be used.

Item SKU: SU-15