Pizza peels are fun and easy CNC router woodworking projects to make. The design is straight-forward and can be done quickly in all design software, such as Vectric Vcarve, Easel, Carbide Create, Carveco, Fusion 360, etc.

Even better, your pizza peel can be completed in a single setup on your CNC router with only 2 or 3 CNC router bits. It can even be done with one bit.

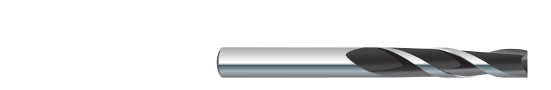

Traditionally, you can make a pizza peel with a single 1/4” compression endmill (also known as an up-down bit). But you also want to round the edges of a pizza peel. That can be done with the same profile line in the design software and using a rounding bit, or round over bit, without changing the setup.

However, there is the one question almost every CNC router own has that wants to make a pizza peel. That is, “How do you cut a taper in a pizza peel on a CNC router?”