A surfacing bit and an end mill are both types of cutting tools used in machining. Technically, a surfacing bit is an endmill and is set up as one in CNC router design software. However, a surfacing bit is designed differently.

A surfacing bit is used to smooth and level out the surface of a CNC router spoilboard, and is used for slab flattening. It typically has a wider, flatter tip than other types of cutters, and can be used to make smooth, even cuts across a surface.

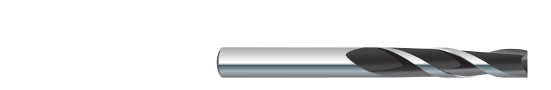

An end mill, on the other hand, is a type of cutter that is used to create pockets, slots, and other features in a piece of material. Endmills have flutes, or cutting edges that are long, and allow for deep cutting. this is called the flute length, or cutting depth. The flute lengths of surfacing bits are much shorter.

Another difference is the bottom-cutting capability. A surfacing bit does not have cutting edges along he full length of the bottom as you might find on endmills. This means you cannot plunge into the material as you would with an endmill. Rather, you would ‘ramp’ into the cut or start from the side of the material and move in from the side.

One other difference is the cutting edges are either removable (insert style) or have the cutting tips welded (brazed) to a central body. This is done to keep costs down since the carbide material used as the cutting edge is an expensive material.

It is necessary to have both surfacing bits and endmills in your CNC router cutting tool arsenal.