Most CNC router bits that you'll use are a "side-cutting end mill," which is just a fancy way of saying that it is a spinning piece of metal that cuts using the sides of the bit. There are two major types: up cut bits and down cut bits.

No one would actually refer to them as such, but some spiral drill bits are up cut bits. You've probably used an up cut bit to drill a hole in the wall to pass a phone or TV cable. It's called an up cut bit because it's channeling all the material it cuts up and away from the hole or groove.

A down cut bit, on the other hand, does the opposite. It pushes the material it cuts down into the groove. That's less efficient, since it sometimes has to grind through the material that doesn't make it out. But the down cut bit has one huge advantage: It makes many fewer burrs. It also provides a more uniform cut (but not a perfect one, more on that later).

Up cut bits are ripping the wood out of the material, and that leaves little shreds of wood where it's torn instead of cut. And sometimes the wood fibers pull too many of their friends out with them, making the cut deeper or wider than it should be. But down cut bits are pushing the cut wood up against the remaining material as they cut, and so they get cleaner cuts.

Check Out: IDC Woodcraft’s Complete CNC Router Bit Set

That cleaner cut means a lot less sanding for you. But understanding how these bits work is important. You can't just swap out the bits and get to work because there's some engineering knowledge that goes into adjusting for their different forces.

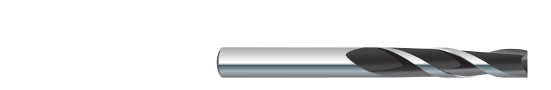

By the way, if you ever lose track of which bits in your set are which, you can look at a bit and twirl it slowly to figure it out. An up cut bit has a cutting edge on the bottom of the bit and it's flutes have an up direction, the same direction as a typical screw. Down bits have the opposite flute direction and no cutting edge on the bottom of the bit.